您的购物车目前是空的!

Beginner’s Guide : 3-Phase Power Lines and Voltage Systems

Beginner's Guide to Track Sockets discussion of various topics Outlets Guide remodeling plans

1. Introduction to 3-Phase Power

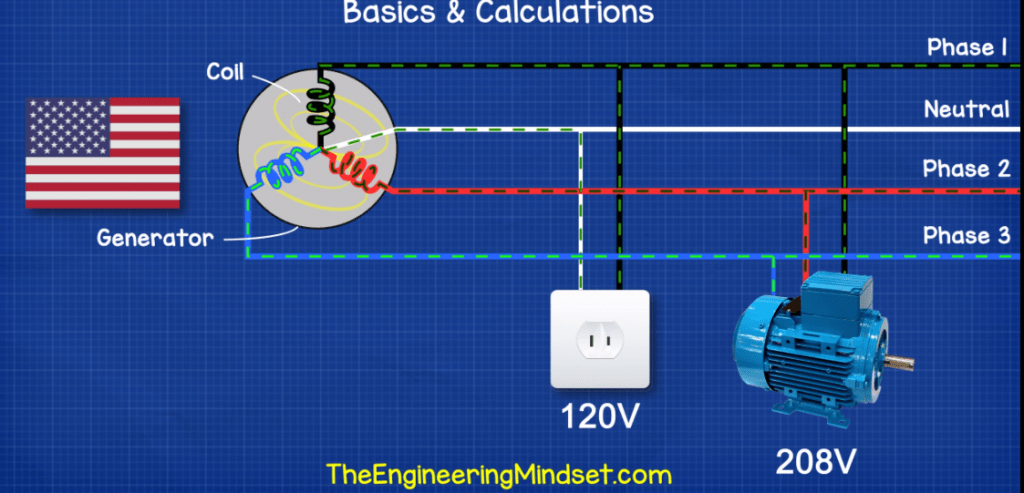

3-phase power is a way to generate, transmit, and distribute alternating current (AC) electricity. It is commonly used in industries, businesses, and large homes.

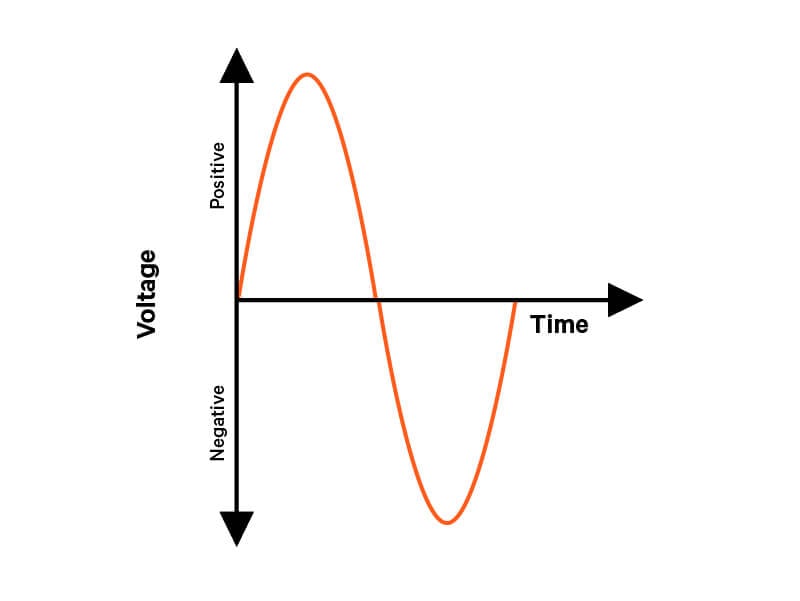

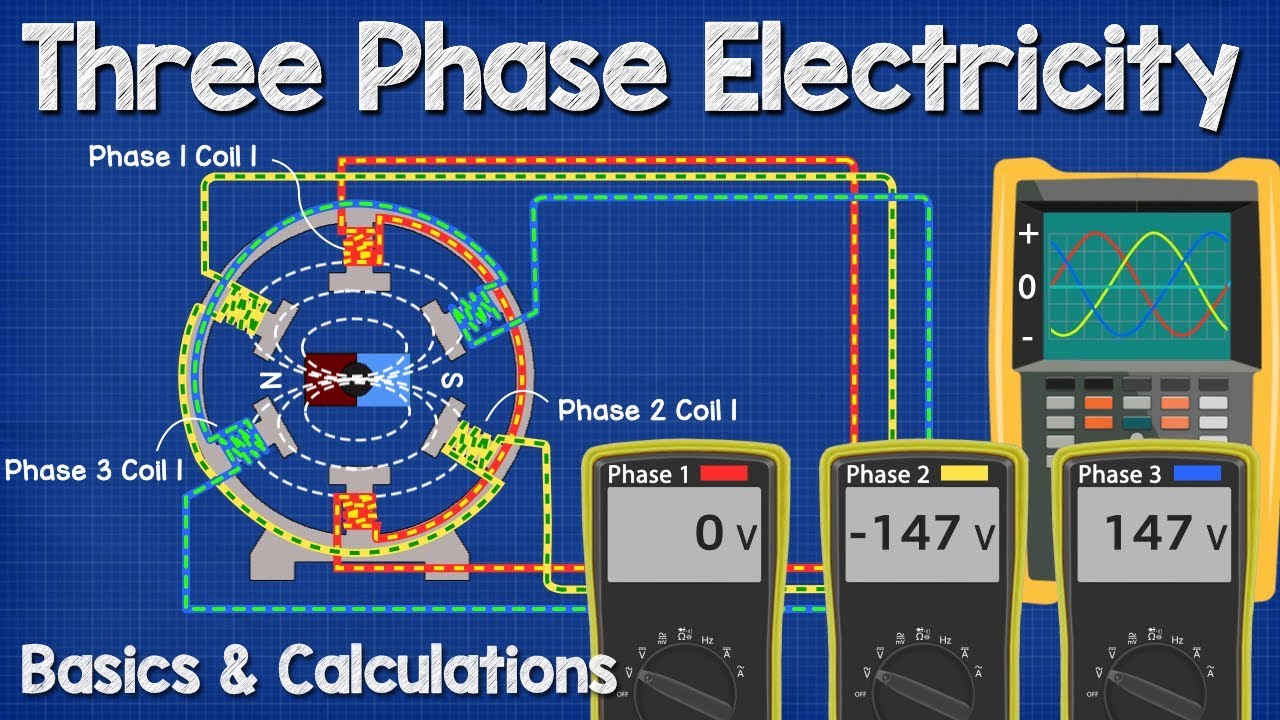

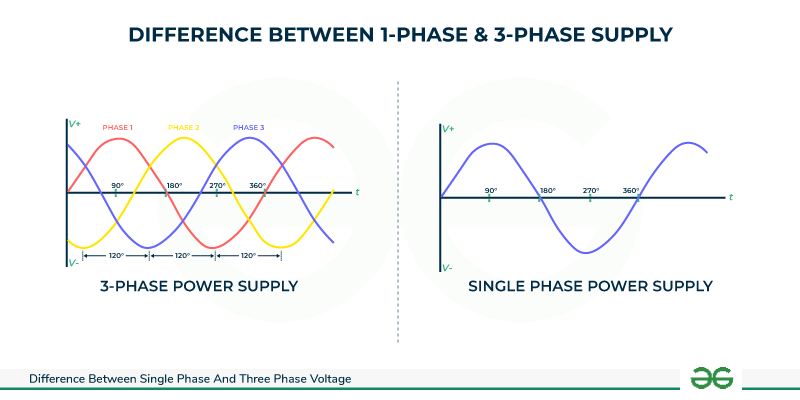

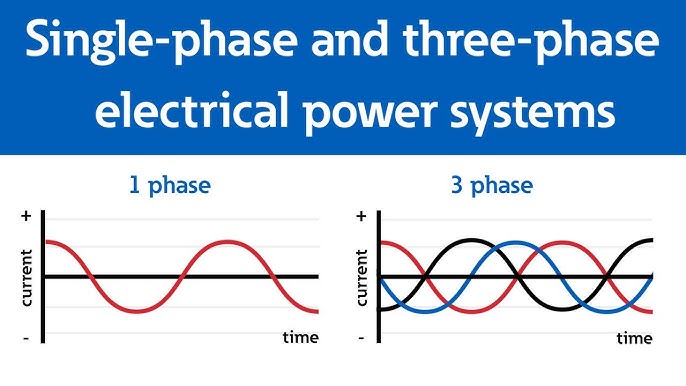

3-phase power uses three alternating currents. These currents are spaced 120 degrees apart. In contrast, single-phase power uses only one alternating voltage cycle. This configuration allows for more efficient power transmission and a more stable power supply, especially for heavy machinery and large electrical systems.

1.1 Definition and Overview of 3-Phase Power

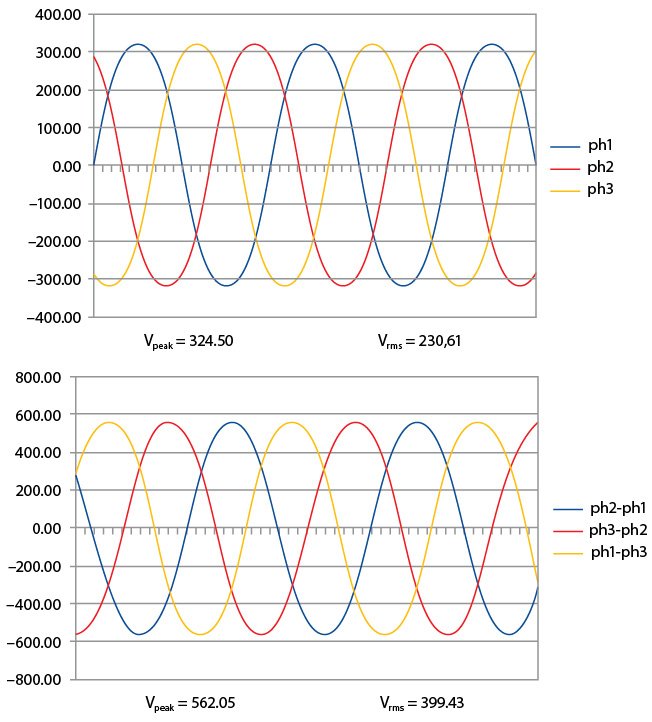

In its simplest form, 3-phase power is a type of polyphase system that consists of three sinusoidal voltages of equal frequency and amplitude. These voltages are out of phase with each other by 120 degrees, meaning they peak at different times. These three phases work together to provide a steady flow of power. This makes them ideal for running large motors and equipment that require reliable electricity.

1.2 Importance of 3-Phase Power in Electrical Systems

The 3-phase power system is crucial for efficient electrical power generation and distribution. It maintains a consistent voltage and current. This is important for industries that use large motors, pumps, and other machines.

3-phase systems are less expensive than single-phase systems because they require less material to transmit power. This ultimately reduces the cost of electrical infrastructure.

1.3 Comparison with Single-Phase Power

Single-phase power is used in homes. However, 3-phase power is preferred for businesses and industries. This is because it is more efficient and stable.

Single-phase systems can have voltage drops and power changes when the load is high. In contrast, 3-phase systems distribute the electrical load evenly. This reduces the likelihood of these issues.

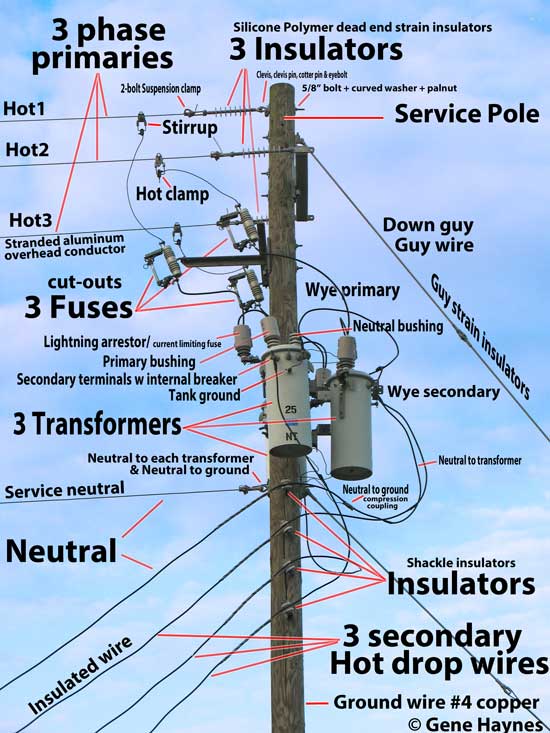

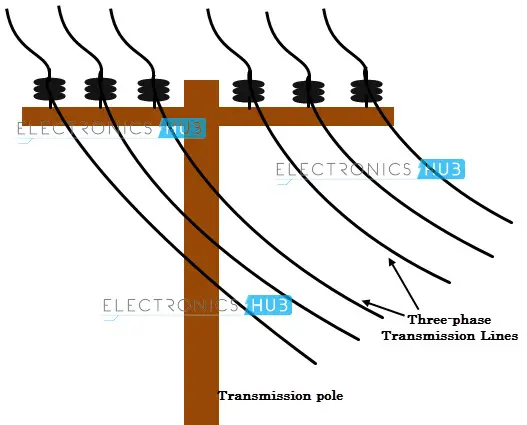

2. What is a 3-Phase Power Line?

A 3-phase power line is the physical infrastructure used to transmit 3-phase electrical power from generation stations to consumers. These lines consist of three wires, each carrying one phase of the power, and often include a neutral wire, depending on the configuration. The power lines are a critical part of the electrical grid, ensuring that large amounts of electricity can be transmitted over long distances with minimal loss.

2.1 Explanation of 3-Phase Power Lines

3-phase power lines are typically composed of three conductors, each associated with one of the three phases of electricity. In some configurations, such as the Wye (or star) configuration, a fourth wire, known as the neutral conductor, is included. This setup allows the system to supply power to both single-phase and 3-phase devices. The spacing and insulation of these wires are carefully designed to prevent short circuits and to handle the high voltages involved in power transmission.

2.2 Components of a 3-Phase Power Line: Conductors, Insulation, and Support Structures

The primary components of a 3-phase power line include conductors, which are typically made of aluminum or copper, insulation materials to prevent electrical leaks, and support structures like poles or towers. Conductors are the core of the power line, carrying the electrical current from the power plant to the end users.

Insulation materials protect these conductors from environmental factors and ensure that the electricity flows safely and efficiently. Support structures, which can be made of wood, steel, or concrete, keep the power lines elevated and secure, preventing them from contacting the ground or other objects.

2.3 Applications of 3-Phase Power Lines in Industrial and Commercial Settings

3-phase power lines are essential in industrial and commercial environments where large amounts of power are required. They are used to power heavy machinery, HVAC systems, and other equipment that operates more efficiently on 3-phase power. Additionally, these power lines are crucial for large buildings, such as shopping malls and hospitals, where consistent and reliable power is necessary to keep operations running smoothly.

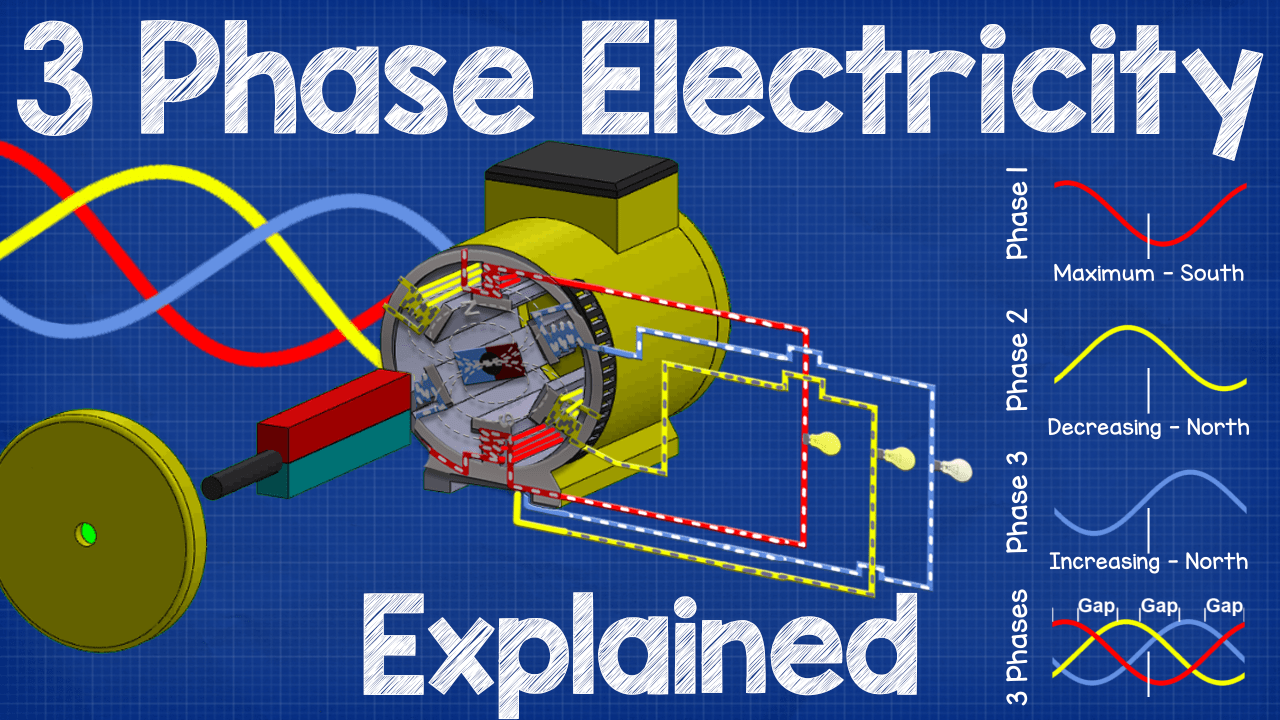

3. The 3-Phase System: How It Works

The 3-phase system is a method of electrical power generation and distribution that uses three separate phases of alternating current, each phase being 120 degrees out of sync with the others. This design allows for a constant flow of energy, minimizing the fluctuations and peaks that occur in single-phase systems.

3.1 Overview of the 3-Phase System

In a 3-phase system, power is made by spinning a coil in a magnetic field. This process generates three AC voltages. These voltages are shifted by 120 degrees from one another.

This system is highly efficient because it ensures that at least one phase is always at its peak voltage, providing continuous power delivery. The three phases work together to produce a more balanced and consistent power supply, making it ideal for running large motors and other industrial equipment.

3.2 Understanding the Phase Angle and Phase Shift

The phase angle in a 3-phase system refers to the degree to which the individual waveforms are out of sync with each other. The 120-degree phase shift between each phase means that as one phase is reaching its maximum voltage, another is in its mid-cycle, and the third is approaching its minimum voltage. This phase relationship is critical for ensuring that the power supply remains stable and that the load is distributed evenly across the system.

3.3 Benefits of the 3-Phase System Over Other Systems

The primary benefit of the 3-phase system is its ability to deliver a constant and reliable power supply. Unlike single-phase systems, which can experience voltage dips and surges, 3-phase systems provide a smoother and more consistent flow of electricity. This makes them ideal for powering large, sensitive equipment that requires a steady power supply. Additionally, 3-phase systems are more efficient in transmitting electricity over long distances, reducing energy losses and lowering operational costs.

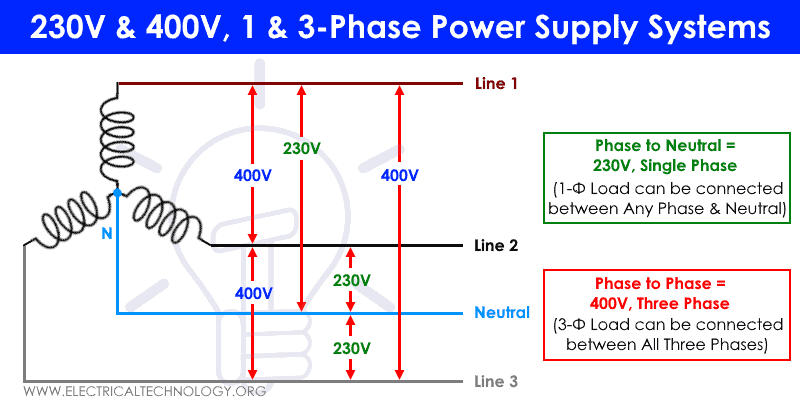

4. 3-Phase Voltage Levels

The voltage levels in 3-phase systems can vary depending on the application and the region. Common voltage levels include 415V and 440V, which are widely used in many countries. Understanding these voltage levels is crucial for designing and operating electrical systems that use 3-phase power.

4.1 Common Voltage Levels: 415V, 440V, and Beyond

In many countries, 415V is the standard voltage level for 3-phase systems, particularly in industrial and commercial settings. This voltage level is sufficient for most applications, providing enough power to run large machinery and equipment. However, in some regions, 440V is used instead, offering a slightly higher voltage that can be beneficial for certain types of equipment. Other voltage levels, such as 380V or 460V, may also be used depending on the specific requirements of the electrical system.

4.2 The Reason Behind 415V Voltage in 3-Phase Systems

The use of 415V in 3-phase systems is primarily due to its efficiency and compatibility with a wide range of equipment. This voltage level provides a good balance between power output and safety, allowing for the effective operation of industrial machines without causing excessive wear or damage to the equipment. Additionally, 415V is a common standard in many parts of the world, making it easier to source compatible equipment and components.

4.3 Differences Between 415V and 440V in Various Applications

While both 415V and 440V are used in 3-phase systems, there are some key differences between the two. 440V systems typically provide a slightly higher power output, which can be beneficial for heavy-duty equipment or applications that require more energy. However, the higher voltage also means that the equipment must be rated for this voltage, which can increase the cost and complexity of the electrical system. In contrast, 415V systems are more widely used and may be more cost-effective for standard industrial applications.

5. Is 240V Single-Phase or 3-Phase?

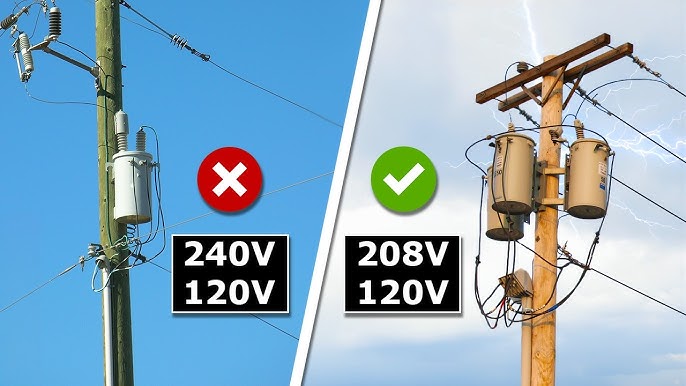

The voltage level of 240V is commonly associated with single-phase power systems, especially in residential settings. However, it can also be part of a 3-phase system, depending on how the system is configured.

5.1 Understanding 240V and Its Usage in Electrical Systems

240V is a common voltage level used in single-phase power systems, particularly in residential homes. In these systems, 240V is typically used to power high-energy appliances, such as ovens, air conditioners, and water heaters. The 240V supply is created by combining two 120V phases, resulting in a higher voltage that can power larger devices.

5.2 Differences Between 240V Single-Phase and 3-Phase Systems

In a single-phase system, 240V is made by adding two 120V phases. In a 3-phase system, 240V can be one phase in a higher voltage setup, like a 415V system. The key difference is that in a 3-phase system, the power is distributed across three wires, each carrying a 240V phase, providing a more balanced and efficient power supply. In contrast, single-phase systems rely on a single phase, which can lead to voltage fluctuations and inefficiencies.

5.3 Applications of 240V in Residential and Commercial Settings

240V is commonly used in residential settings for powering high-demand appliances, as mentioned earlier. In commercial settings, 240V may be part of a 3-phase system, providing power to equipment that requires a stable and efficient supply. Understanding how 240V is used in different settings is important for designing electrical systems that meet the specific needs of the application.

6. Phase Conductors in 3-Phase Systems

The conductors in a 3-phase system are responsible for carrying the electrical current from the power source to the end users. Understanding the role and configuration of these conductors is crucial for ensuring the safe and efficient operation of the system.

6.1 Number of Wires in a 3-Phase System

A typical 3-phase system consists of three live wires, each carrying one of the phases, and often includes a neutral wire. The three live wires are essential for maintaining the phase relationship and ensuring a balanced power supply. In some cases, an additional ground wire may be included to enhance safety.

6.2 Role of the Neutral Conductor in 3-Phase Power

The neutral conductor in a 3-phase system serves as a return path for the current and helps to stabilize the voltage levels. In a Wye configuration, the neutral wire connects to the center of the Wye, providing a reference point for the voltages and ensuring that the system operates within its designed parameters. The neutral wire also allows for the use of single-phase loads within a 3-phase system, providing flexibility in how the power is distributed.

6.3 The Importance of Phase Conductors in Power Transmission

Phase conductors are the backbone of the 3-phase system, carrying the electrical current from the power generation source to the consumers. The size and material of the conductors are carefully chosen to ensure they can handle the current without overheating or causing excessive voltage drops. Proper maintenance of these conductors is essential for preventing power outages and ensuring the reliability of the electrical system.

7. Comparing 3-Phase and 2-Phase Systems

While 3-phase systems are the standard in most industrial and commercial applications, 2-phase systems were once commonly used in certain regions. Understanding the differences between these systems can help in designing and maintaining electrical infrastructure.

7.1 Voltage Levels in 2-Phase Systems

2-phase systems typically use two voltage levels that are 90 degrees out of phase with each other. This system was once used in certain regions but has largely been replaced by 3-phase systems due to the latter’s efficiency and stability. The voltage levels in a 2-phase system are usually lower than those in a 3-phase system, limiting the amount of power that can be transmitted.

7.2 The Decline of 2-Phase Systems and the Rise of 3-Phase Systems

The decline of 2-phase systems can be attributed to the superior efficiency and power handling capabilities of 3-phase systems. As industrial and commercial power demands increased, the limitations of 2-phase systems became apparent, leading to their replacement with 3-phase systems in most applications. Today, 3-phase systems are the standard for power generation, transmission, and distribution, while 2-phase systems are largely obsolete.

7.3 Applications and Limitations of 2-Phase Systems

Although 2-phase systems are largely obsolete, they may still be found in some older installations or in specific applications where the power demands are low. However, their limitations in terms of power transmission and efficiency make them unsuitable for modern industrial or commercial use. Understanding these limitations is important for anyone involved in the maintenance or upgrading of older electrical systems.

8. Single-Phase Power Supply: An Overview

Single-phase power is the most common type of electrical power used in residential homes and small businesses. It is simpler and less expensive to install than 3-phase power, making it the preferred choice for low-power applications.

8.1 Definition and Uses of Single-Phase Power

Single-phase power is an AC power supply that uses a single sinusoidal voltage wave. It is commonly used in residential homes to power lights, appliances, and other low-power devices. The simplicity of single-phase power makes it easy to install and maintain, although it is less efficient for powering large loads.

8.2 Common Applications in Residential Homes and Small Businesses

In residential homes, single-phase power is used to power most household appliances, including lights, refrigerators, and televisions. It is also used in small businesses for powering computers, office equipment, and other low-demand devices. The relatively low voltage of single-phase power (typically 120V or 240V) makes it safe for use in these environments.

8.3 Comparing Single-Phase with 3-Phase in Terms of Efficiency and Cost

While single-phase power is sufficient for most residential and small business applications, it is less efficient than 3-phase power for larger loads. 3-phase power provides a more stable and consistent power supply, reducing the risk of voltage drops and equipment damage. However, the higher cost and complexity of installing 3-phase power make it less suitable for small-scale applications where the power demands are lower.

9. High Voltage Power Transmission

High voltage power transmission is the process of transmitting electricity at high voltages over long distances. This method is used to reduce power losses and improve the efficiency of the electrical grid.

9.1 Understanding High Voltage in Power Transmission

High voltage is essential for efficient power transmission because it reduces the amount of current that needs to be carried by the conductors. This, in turn, reduces the amount of heat generated by the conductors and minimizes energy losses. High voltage transmission is typically used for transporting electricity from power plants to substations, where it is then stepped down to lower voltages for distribution to homes and businesses.

9.2 Role of High Voltage in Reducing Transmission Losses

One of the main advantages of high voltage transmission is its ability to reduce energy losses over long distances. By increasing the voltage, the current in the transmission lines is reduced, which lowers the resistive losses in the conductors. This makes high voltage transmission more efficient than low voltage transmission, particularly over long distances.

9.3 Safety Considerations in High Voltage Systems

High voltage systems require careful design and maintenance to ensure safety. Insulation, grounding, and protective devices are critical components of these systems, preventing electrical shocks and equipment damage. Regular inspections and maintenance are also necessary to identify and address potential issues before they lead to power outages or accidents.

10. Power Track Systems and 3-Phase Power

Power track systems are a modern solution for distributing power in commercial buildings. These systems are designed to work seamlessly with 3-phase power, providing flexibility and efficiency in electrical installations.

10.1 What are Power Track Systems?

Power track systems are modular power distribution systems that allow for easy and flexible installation of electrical outlets and devices. These systems consist of a track that is installed along walls or ceilings, with outlets and other devices easily added or repositioned along the track. This makes power track systems ideal for environments where the electrical needs may change frequently.

10.2 Integrating Power Track Systems with 3-Phase Power

Power track systems can be easily integrated with 3-phase power, providing a flexible and efficient solution for distributing power in commercial buildings. The ability to distribute 3-phase power along a track system allows for the easy connection of equipment and devices that require different voltage levels or phases. This flexibility is particularly useful in environments like offices, workshops, and factories, where power requirements may change over time.

10.3 Advantages of Power Track Systems in Commercial Buildings

The main advantages of power track systems in commercial buildings include their flexibility, ease of installation, and ability to accommodate changing power needs. These systems allow for quick and easy adjustments to the electrical layout without the need for extensive rewiring. Additionally, power track systems can help to reduce clutter and improve safety by minimizing the need for extension cords and other temporary power solutions.

11. Track Socket: Modern Power Solutions

Track sockets are a key component of power track systems, providing a convenient and flexible way to connect electrical devices. These sockets can be easily repositioned along the track, allowing for quick adjustments to the electrical layout.

11.1 Introduction to Track Sockets

Track sockets are specialized electrical outlets designed to work with power track systems. Unlike traditional outlets, which are fixed in place, track sockets can be moved along the track to provide power wherever it is needed. This flexibility makes them ideal for environments where the power requirements may change frequently, such as offices, workshops, and retail spaces.

11.2 Benefits of Using Track Sockets in Electrical Systems

The primary benefit of using track sockets is their flexibility. They allow for quick and easy adjustments to the electrical layout without the need for extensive rewiring. This can save time and money during installation and make it easier to accommodate changes in the power requirements of a space. Additionally, track sockets can help to reduce clutter and improve safety by minimizing the need for extension cords and other temporary power solutions.

11.3 Compatibility of Track Sockets with 3-Phase and Single-Phase Systems

Track sockets are compatible with both 3-phase and single-phase systems, making them a versatile solution for a wide range of applications. In a 3-phase system, track sockets can be used to distribute power to different devices and equipment, providing a flexible and efficient power distribution solution. In a single-phase system, track sockets offer the same flexibility and ease of use, making them ideal for residential and small business applications.

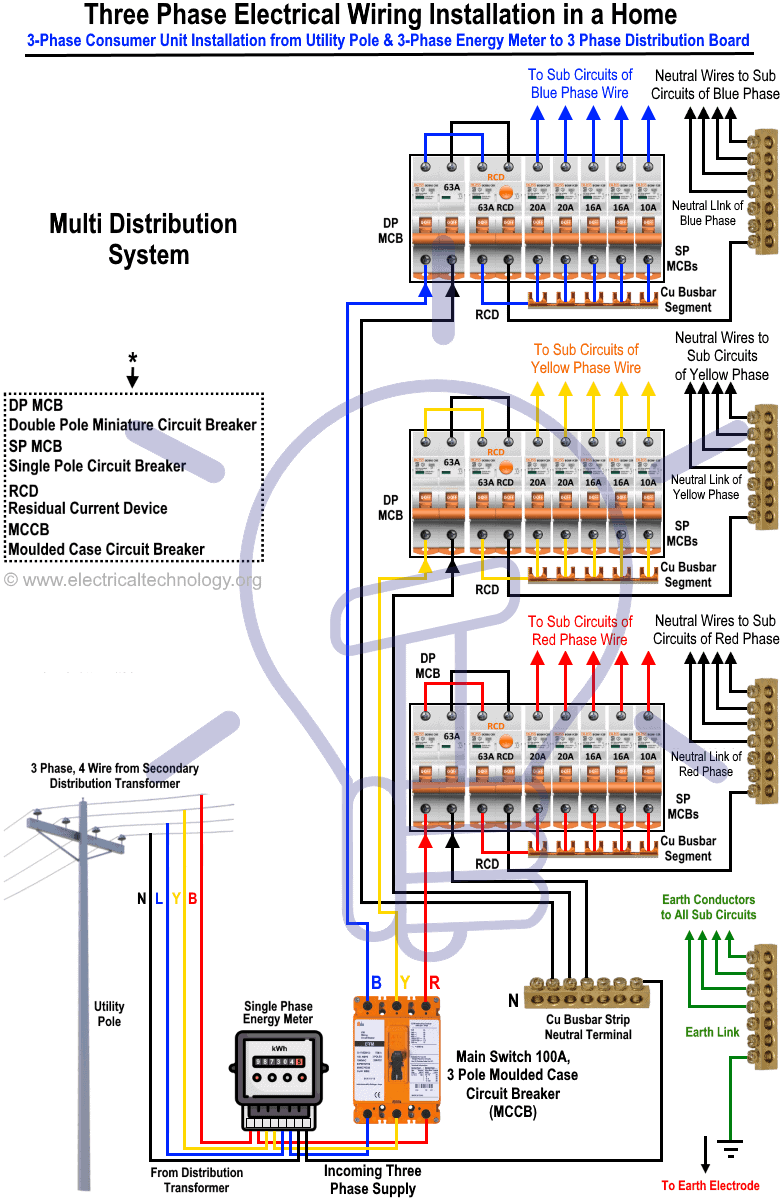

12. Electrical Systems in Commercial Buildings

Commercial buildings have unique electrical requirements that often necessitate the use of 3-phase power and modern distribution systems like power tracks and track sockets. Understanding these systems is essential for designing efficient and reliable electrical infrastructure.

12.1 The Role of 3-Phase Power in Commercial Settings

3-phase power is commonly used in commercial buildings due to its efficiency and ability to handle large power loads. It is used to power elevators, HVAC systems, lighting, and other essential equipment. The use of 3-phase power in commercial settings ensures a stable and reliable power supply, reducing the risk of outages and equipment damage.

12.2 Designing Electrical Systems for Efficiency

Efficiency is a key consideration when designing electrical systems for commercial buildings. This involves selecting the right voltage levels, using efficient power distribution systems, and ensuring that the system can accommodate future power needs. Power track systems and track sockets can play a crucial role in achieving this efficiency, providing flexibility and reducing the need for costly rewiring.

12.3 The Use of Track Sockets and Power Tracks in Modern Electrical Installations

Track sockets and power tracks are becoming increasingly popular in modern electrical installations due to their flexibility and ease of use. These systems allow for quick and easy adjustments to the electrical layout, making them ideal for environments where the power requirements may change frequently. By incorporating these systems into the design of commercial buildings, electrical engineers can create more adaptable and efficient power distribution networks.

13. The Wye Configuration in 3-Phase Systems

The Wye configuration is one of the most common methods for connecting a 3-phase power system. Understanding this configuration is essential for anyone involved in the design or maintenance of 3-phase electrical systems.

13.1 Overview of the Wye Configuration

In a Wye configuration, the three phase conductors are connected to a common point, known as the neutral point, forming a Y-shaped circuit. This configuration allows for the use of both 3-phase and single-phase loads within the same system, providing flexibility in how the power is distributed. The Wye configuration is commonly used in power distribution networks and is preferred for its simplicity and versatility.

13.2 Advantages of Wye Configuration in Power Distribution

The Wye configuration offers several advantages in power distribution, including the ability to supply both high and low voltage loads from the same system. This makes it ideal for applications where a mix of 3-phase and single-phase equipment is used. Additionally, the Wye configuration provides a stable neutral point, which helps to maintain voltage balance and reduce the risk of equipment damage.

13.3 Wye vs Delta Configuration: Which is Better?

The choice between Wye and Delta configurations depends on the specific requirements of the electrical system. The Wye configuration is preferred for its versatility and ability to supply both 3-phase and single-phase loads. In contrast, the Delta configuration is often used in applications where high power is required, such as in heavy industrial equipment. Each configuration has its own advantages and disadvantages, and the choice between them should be based on the specific needs of the application.

14. Safety and Maintenance of 3-Phase Systems

Safety and maintenance are critical aspects of operating 3-phase systems. Regular inspections and proper maintenance can prevent accidents and ensure the reliability of the electrical system.

14.1 Common Safety Protocols for 3-Phase Systems

Safety protocols for 3-phase systems include proper grounding, the use of protective devices, and regular inspections. Grounding helps to prevent electrical shocks by providing a safe path for any stray current to flow to the ground. Protective devices, such as circuit breakers and fuses, are used to disconnect the power in case of a fault, preventing damage to the equipment and reducing the risk of fire.

14.2 Maintenance of 3-Phase Power Lines and Systems

Regular maintenance of 3-phase power lines and systems is essential for preventing power outages and ensuring the reliability of the electrical grid. This includes inspecting the conductors, insulators, and support structures for signs of wear or damage, as well as testing the system for proper operation. Maintenance tasks should be carried out by qualified personnel to ensure that all safety protocols are followed.

14.3 Troubleshooting Common Issues in 3-Phase Systems

Troubleshooting common issues in 3-phase systems involves identifying and addressing problems such as voltage imbalances, phase loss, and equipment malfunctions. Voltage imbalances can cause overheating and damage to equipment, while phase loss can lead to power outages. Proper troubleshooting techniques, combined with regular maintenance, can help to prevent these issues and ensure the continued operation of the electrical system.

15. Future Trends in 3-Phase Power Systems

The field of 3-phase power systems is constantly evolving, with new technologies and innovations improving efficiency, reliability, and safety. Understanding these trends can help electrical engineers and designers stay ahead of the curve.

15.1 Innovations in Power Track and Track Socket Technologies

Innovations in power track and track socket technologies are making these systems more versatile and easier to use. Advances in materials and design are allowing for the creation of more compact and efficient systems, which can be easily integrated into a wide range of applications. These innovations are helping to drive the adoption of power track systems in both commercial and residential settings.

15.2 The Impact of Smart Grid Technologies on 3-Phase Systems

Smart grid technologies are transforming the way 3-phase systems are managed and operated. These technologies allow for real-time monitoring and control of the electrical grid, improving efficiency and reducing the risk of outages. Smart grid systems can automatically adjust the distribution of power based on demand, helping to balance the load and prevent overloading of the system.

15.3 The Future of High Voltage Transmission Systems

The future of high voltage transmission systems is likely to involve even higher voltages and more efficient transmission methods. Advances in materials and technology are allowing for the creation of transmission lines that can carry more power over longer distances with minimal losses. These developments will be critical for meeting the growing demand for electricity in the coming years.

FAQs

What are 3-phase power lines?

Is 3-phase 415V or 440V?

Is 240V single-phase or 3-phase?

Why is 3-phase voltage 415 volts?

If power lines are 3 phase, how does it change to a single phase before entering your main circuit panel?

- Wowsocket: Your Trusted Track Socket Factory for UK-Compliant Power Solutions

- Track Socket UK: The Ultimate Guide to Choosing and Installing the Right Power Solution

- Track Sockets in the Netherlands: The Ultimate Solution for Smart Homes

- Les Prises de Courant sur Rail en France : La Solution Électrique Flexible et Intelligente pour Votre Maison

- UK Track Sockets: The Ultimate Smart Power Solution for Your Home

13,068 点击次数

发表回复